|

|

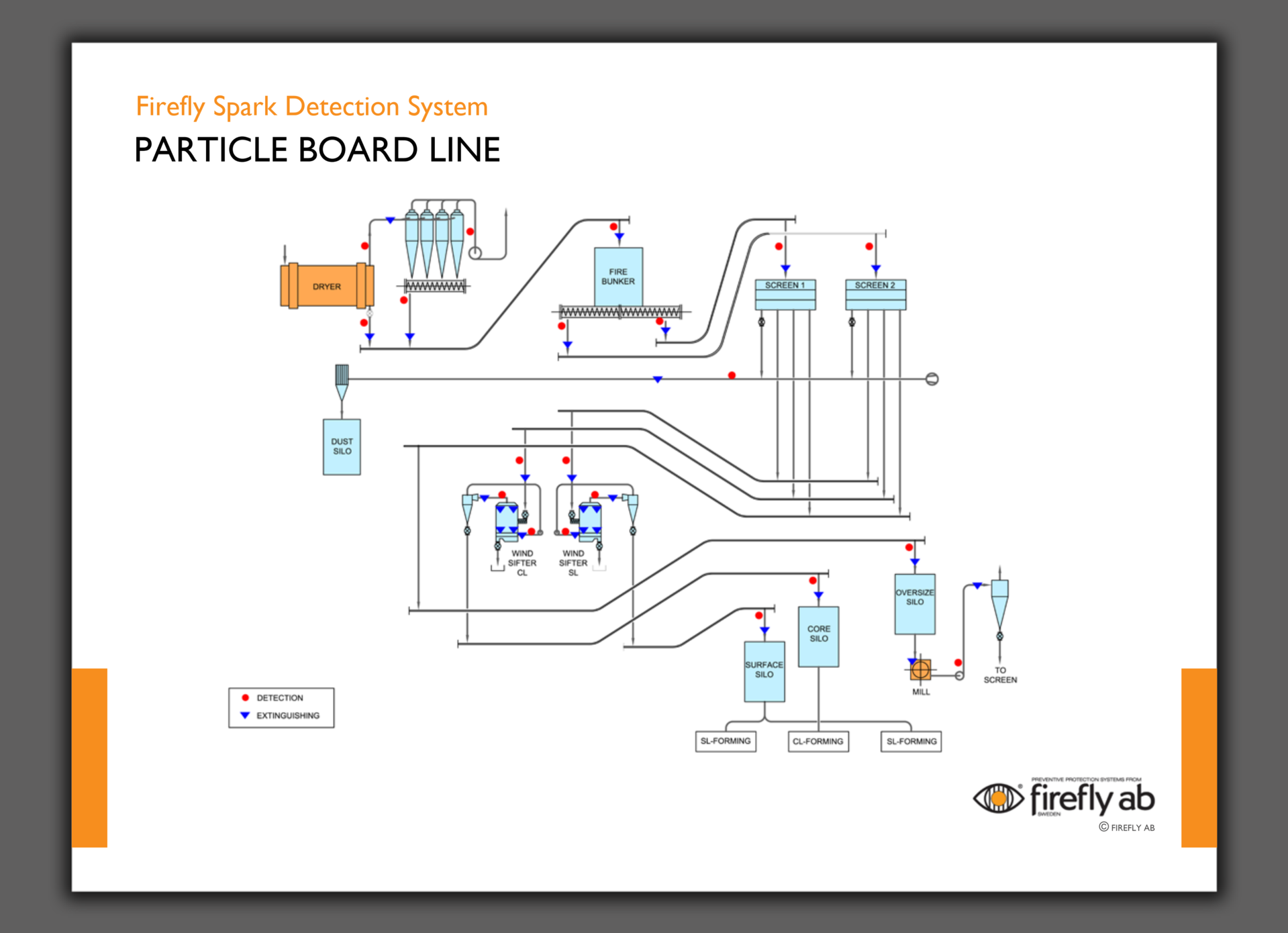

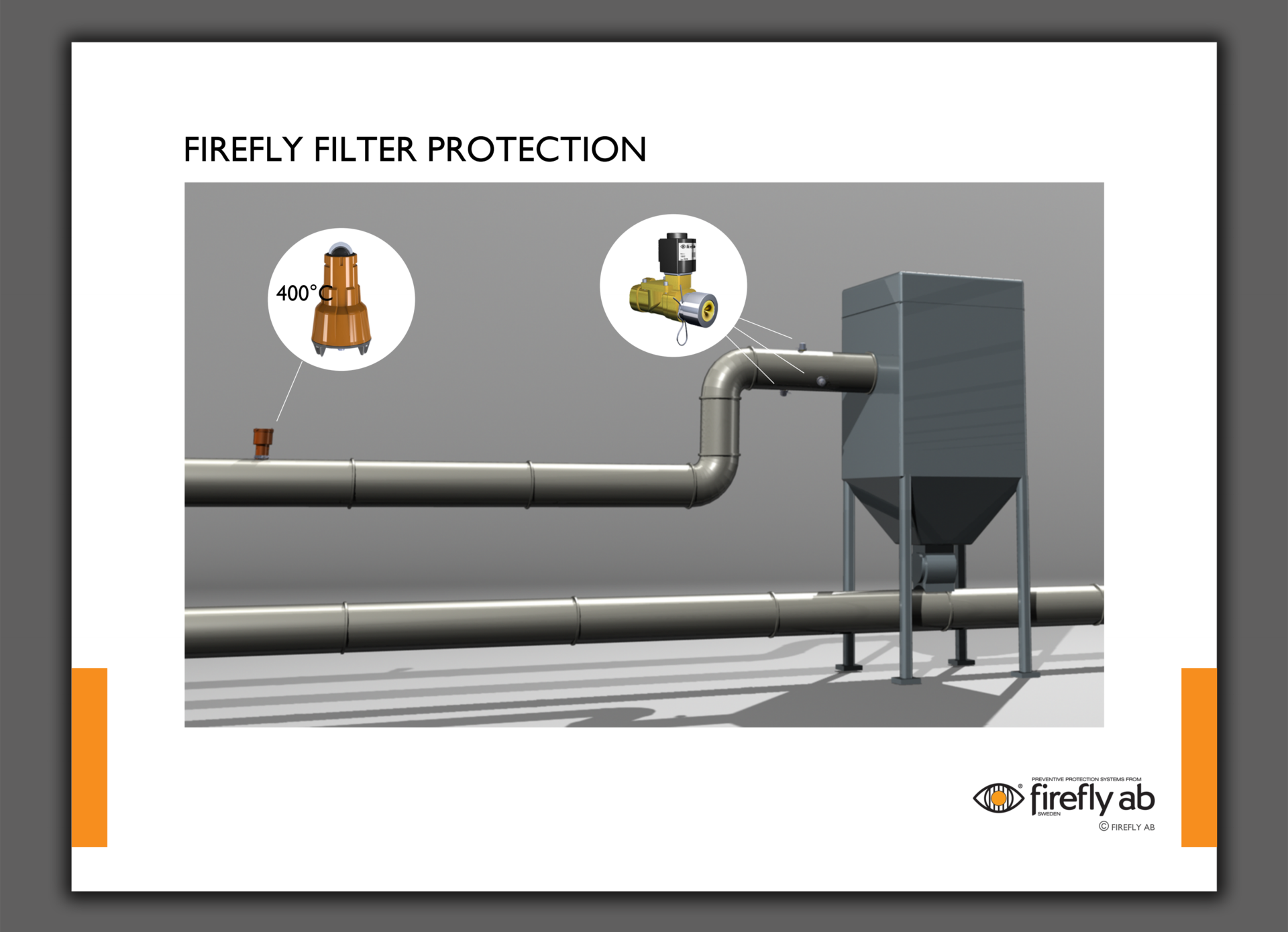

Wood Panel The wood panel industry has been experiencing problems with fire and dust explosions for many years. Up to today, these problems haven't been eliminated. And unfortunately as production increases, so does the risk for fire and explosions. 1.Particle Board High-risk areas in a particle board factory are dryer(s), dryer cyclones, screens, mills, wind sifters, silos, line extraction, sanding/saws as well as the press. Dangerous sparks and hot particles can be generated in the process which can lead to loss of revenue and/or human life as well as major damage to the production line and machinery. Firefly offers many Spark Detection and Quick Suppression solutions for the particle board industry. By tailoring a fire protection system using fast IR-radiation detection and flame detection in combination with effective water spray extinguishing and water mist suppression, Firefly aims to avoid costly fires and dust explosions in particle board factories. 2.MDF High-risk areas in a MDF factory are dryer(s), fiber/dosing bins, wind sifters, forming stations, line extraction, sanding as well as the press. Dangerous sparks and hot particles can be generated in the process that can lead toloss of revenue and/or human life aswell as major damage to the production line and machinery. By tailoring a fire protection system using fast IR-radiation detection and flame detection in combination with effective water spray extinguishing and water mist suppression, Firefly aims to avoid costly fires and dust explosions in MDF factories. 3.OSB High-risk areas in an OSB factory are dryer(s), screening, dry bin, extraction, sanding as well as the press. Dangerous sparks and hot particles can be generated in the process that can lead to loss of revenue and/or human life as well as major damage to the production line and machinery. By tailoring a fire protection system using fast IR-radiation detection and flame detection in combination with effective water spray extinguishing and water mist suppression, Firefly aims to avoid costly fires and dust explosions in OSB factories. 4.Plywood High-risk areas in a plywood factory are filters, silos, sanding and panel sizing. Dangerous sparks and hot particles can be generated in the process that can lead to loss of revenue and/or human life as well as major damage to the production line and machinery. A sanding machine is a high risk area in your process. The fine dust generated can, when ignited, give rise to severe dust explosions and rapid spread of fire. "Firefly's SanderGuard keeps you in production" By tailoring a fire protection system using fast IR-radiation detection and flame detection in combination with effective water spray extinguishing and water mist suppression, Firefly aims to avoid costly fires and dust explosions in plywood factories. 5.FIREFLY PRESSGUARD® It is well-known in the wood panel industry that a fire in a press spreads extremely quickly. A small flame can, in just a couple of seconds, develop into a large-scale press fire with devastating consequences/losses. Combustible material (wood fibres, dust, various types of oil and wax), oxygen and ignition sources (often generated due to friction) are always present in and around a press. Considering that these are the parameters needed to start a fire, the question to be asked would not be if a fire will occur in a continuous press, but rather when. The Firefly PressGuard®, is a Quick Suppression System that consists of a detection- and water mist suppression system. The detection system is built upon a range of different detectors suitable for usage in different areas of a press, this to ensure the best possible accuracy and reaction time. The water mist suppression system uses a lower amount of water to minimise secondary damage/losses. 6.FIREFLY SANDERGUARD™ The fine dust generated by a sanding machine can, when ignited, give rise to severe dust explosions and rapid spread of fire. Firefly's SanderGuard™ system solution is designed for all types of sanders, using quick flame detection inside the sanding machine and water mist suppression, providing optimal protection of this important link in the production chain.

|