|

|

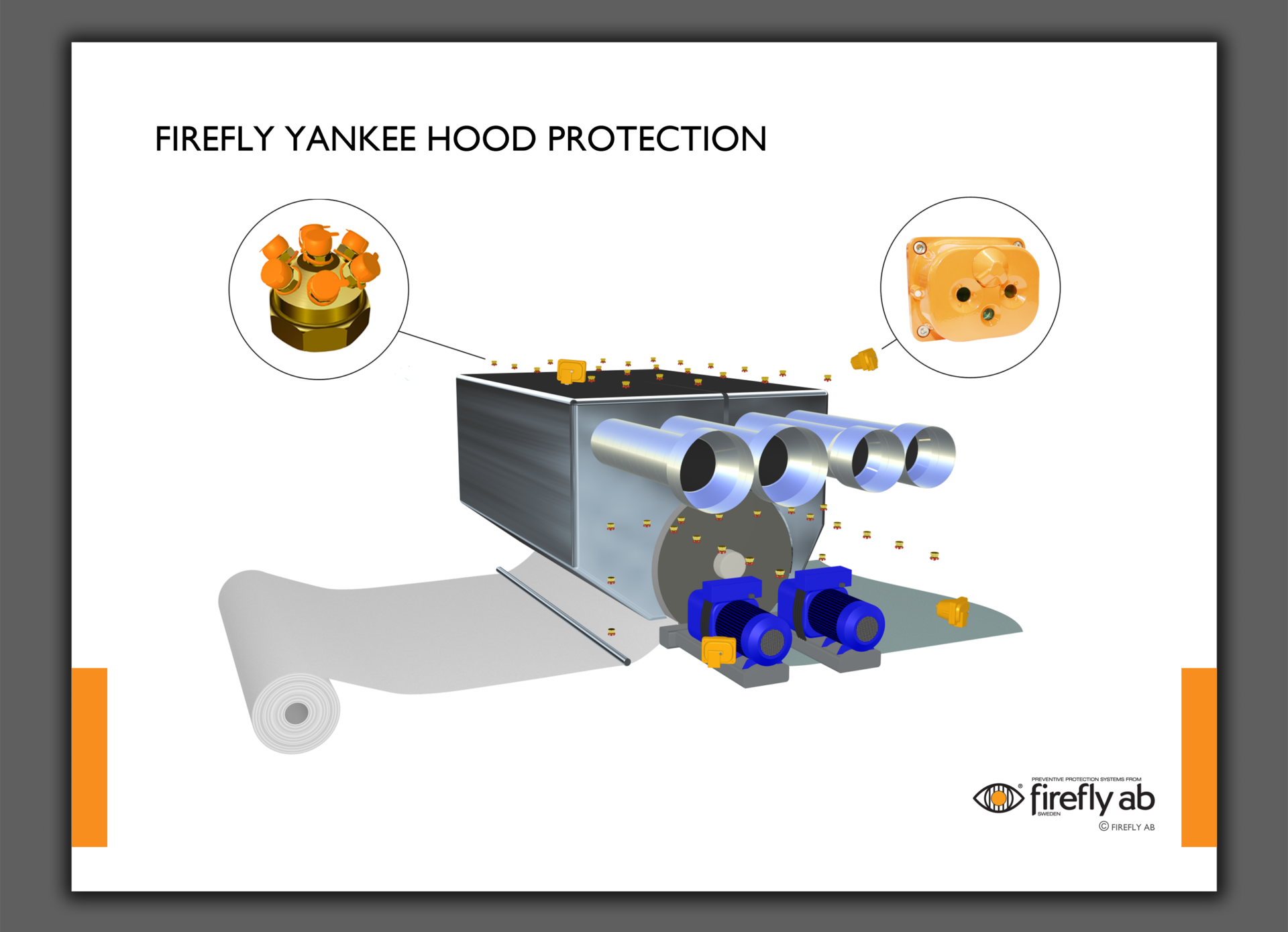

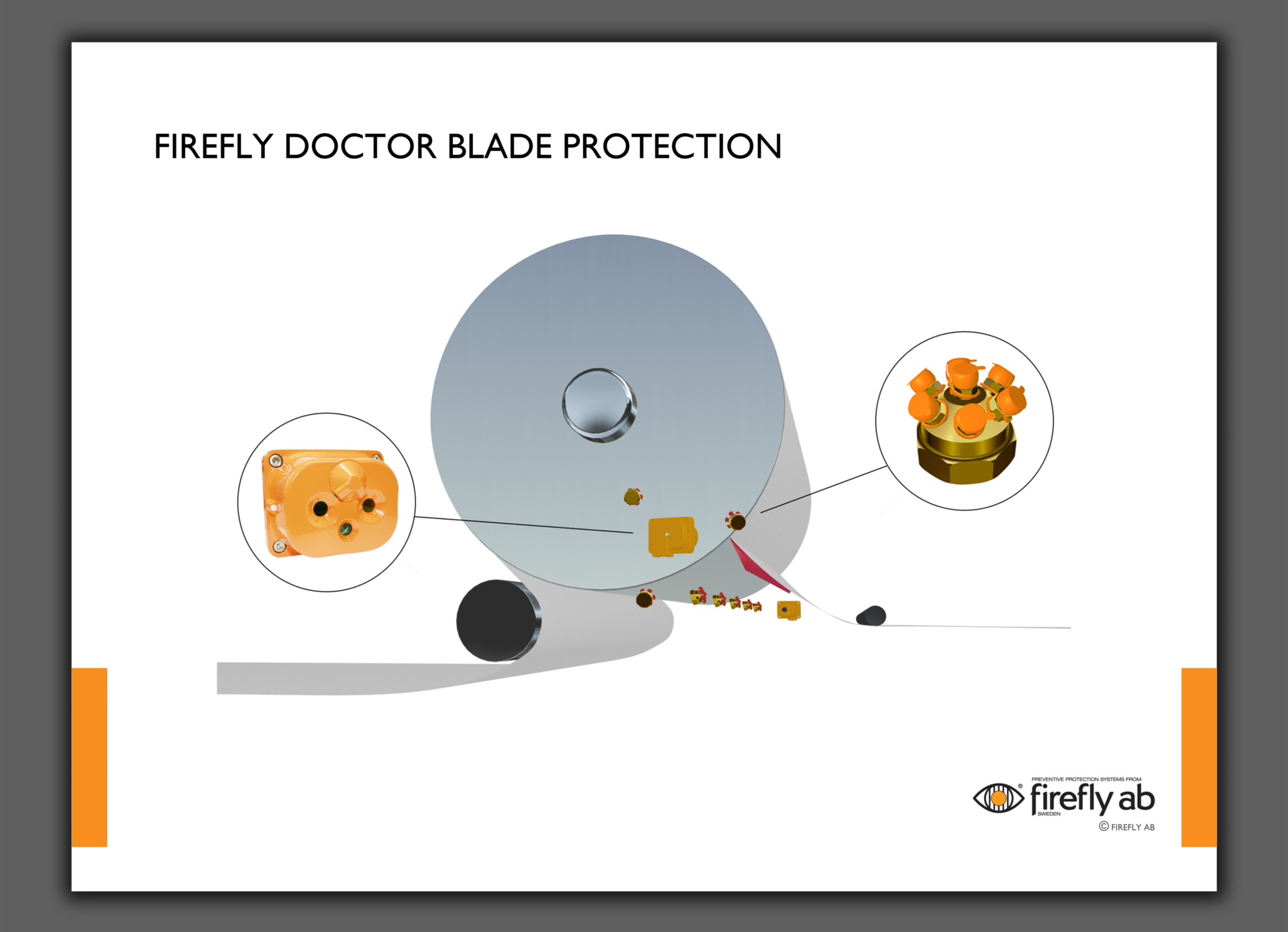

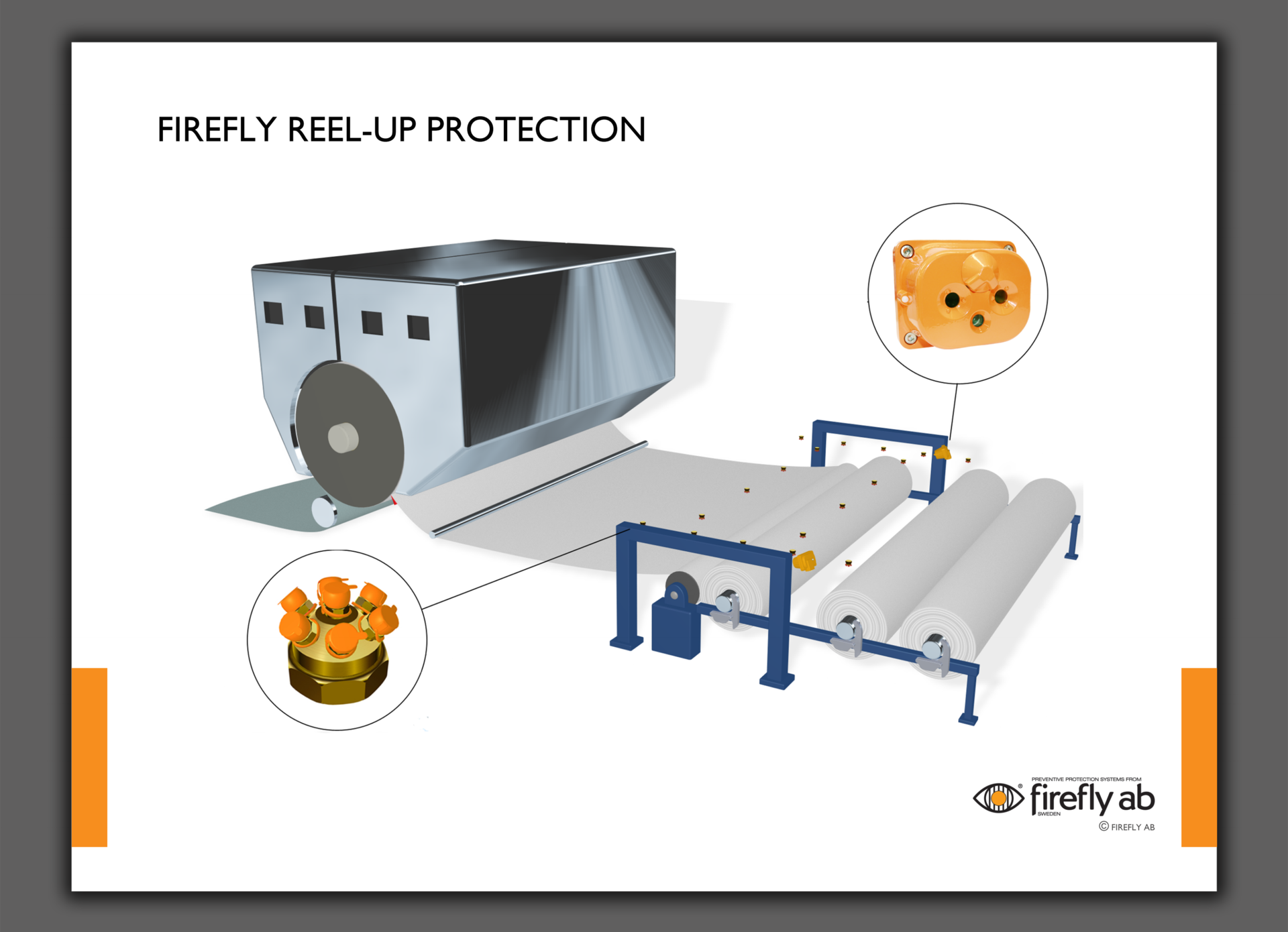

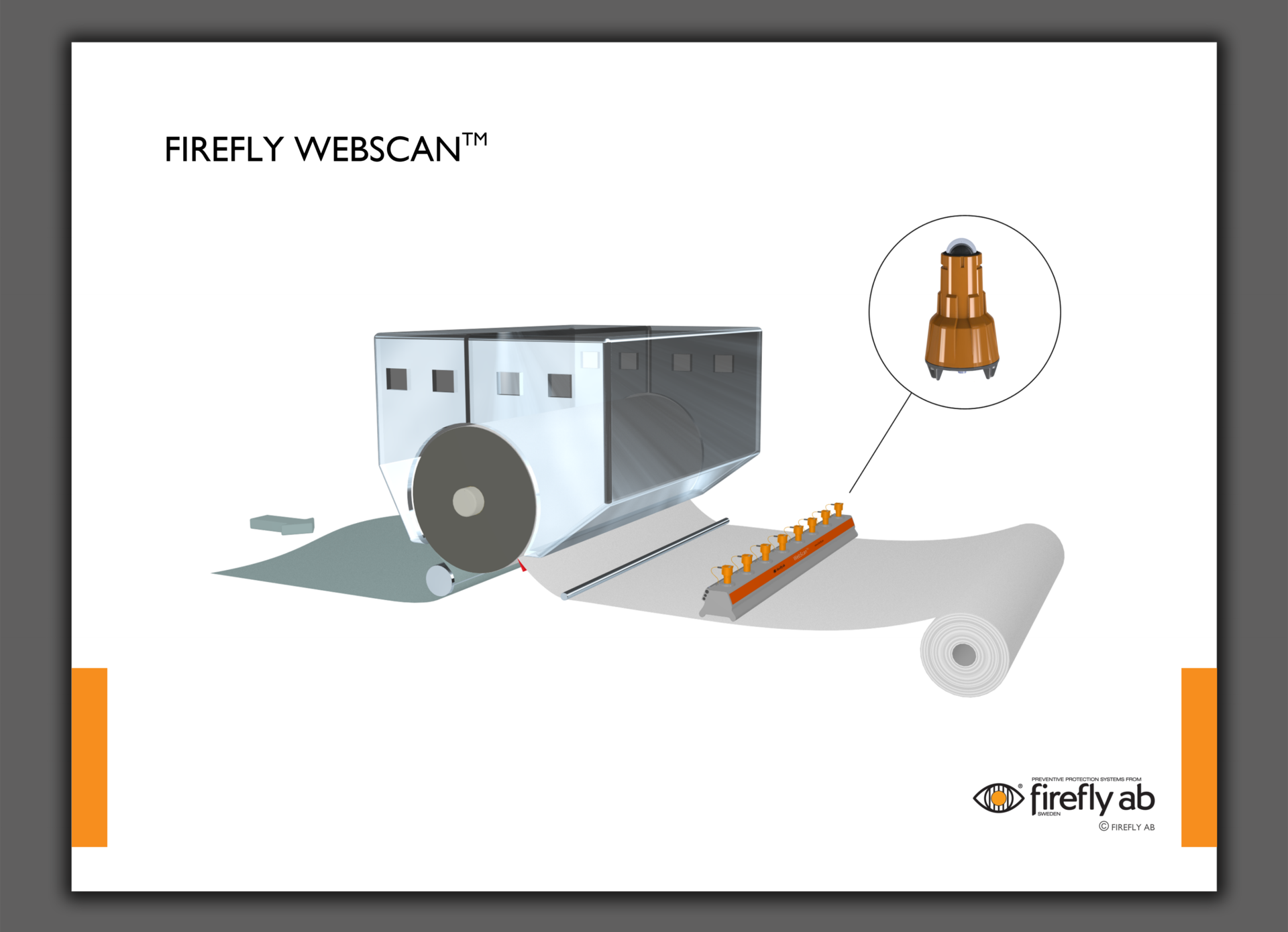

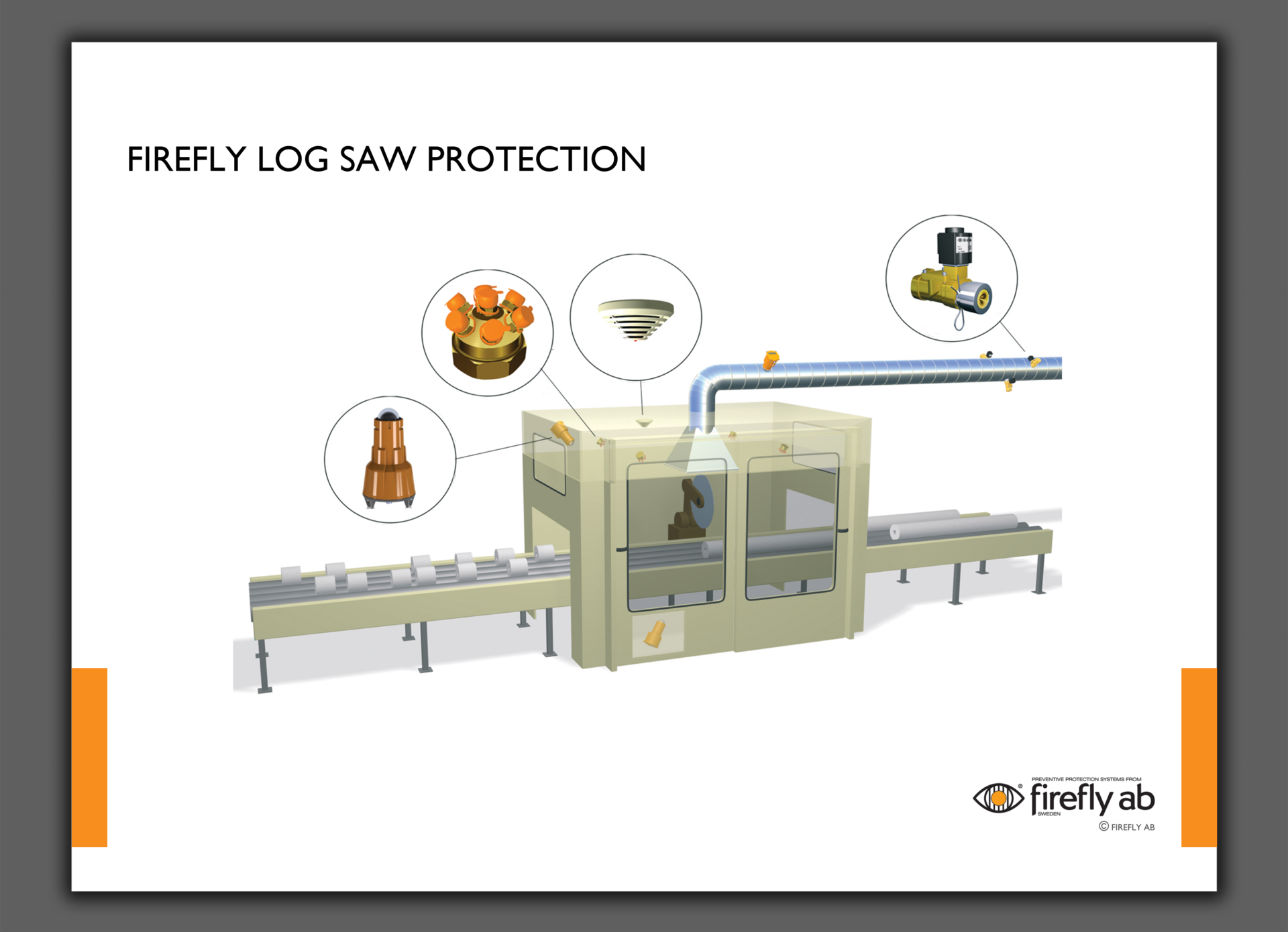

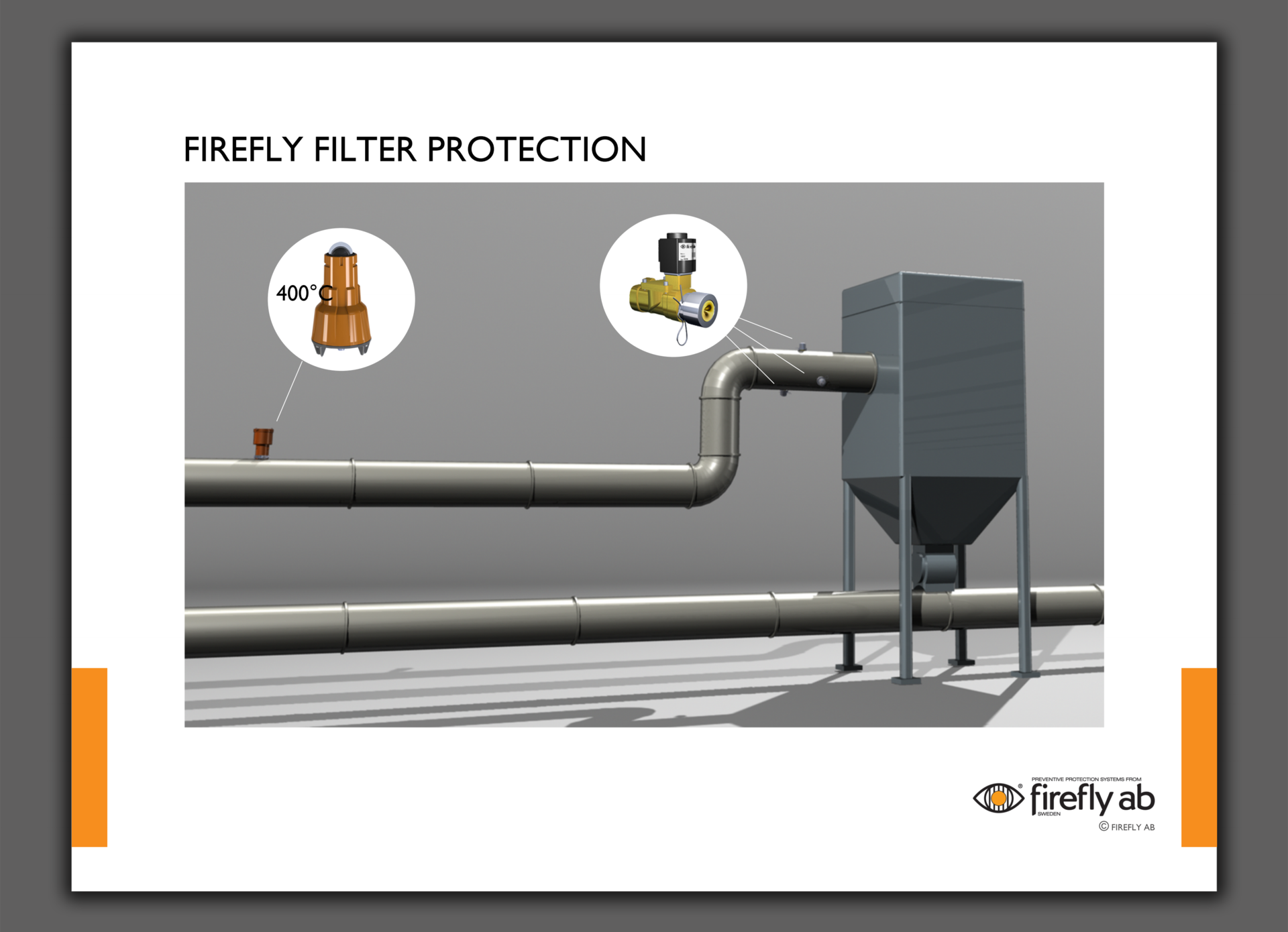

FIRE PROTECTION FOR THE TISSUE & PAPER INDUSTRY FIRE PROTECTION SOLUTIONS FOR TISSUE MANUFACTURING The worst and most feared scenario is that ignition sources created by a production-related problem, such as sparks and hot particles from the Yankee Hood, are embedded within the tissue reel and transferred to the warehouse. The typical frequency of this scenario is low but if and when it happens, the consequences are devastating. Firefly offers detection of sparks and suppression of flames within seconds around the Doctor Blade and Yankee dryer using a combination of the Spark Detection and Quick Suppression system with optical flame detectors that can detect small flames at an early stage, over a large area, combined with water mist suppression. FIREFLY WEBSCAN™ To prevent hot particles from being transferred into the mother roll, a Firefly WebScan™ system can be installed between the Doctor Blade and the reel-up of the mother roll. The WebScan™ system continuously scans the tissue web by using extremely fast IR-sensors above the web. Firefly WebScan™ is able to pinpoint possible ignition sources and in case of an indication, the contaminated mother roll should be put in quarantine. FIRE PROTECTION SOLUTIONS FOR TISSUE CONVERTING In the Log Saw enclosure it is vital to detect and suppress flames within seconds because a fire in this area can spread very quickly. Firefly's Quick Suppression System offers a solution that combines optical UV/IR fire sensors that can detect small flames at an early stage , over a large area, with fast water mist suppression. In order to avoid dust filter fires and explosions, ignition sources in the extraction system need to be detected and extinguished. By installing Firefly Spark Detection system you get extremely fast IR sensors that can detect sparks and hot particles. Depending on the process, the aim of the system is to eliminate ignition sources by extinguishing with water, using isolation and CO2, or diverting the air flow. SOLUTIONS FOR THE PULP INDUSTRY The pulp industry has been experiencing problems with fire and dust explosions for a long time. Problem areas in a pulp factory are flash dryers and slab presses. These parts of your production are vulnerable to possible fire and dust explosions. Dangerous sparks and hot particles can be generated in your process that can lead to loss of revenue and/or human life as well as major damage to your production line and machinery. By using fast IR sensors Firefly can detect sparks and hot particles and eliminate them with steam, water spray or CO2, before they create a problem FIRE PROTECTION SOLUTIONS FOR THE PAPER INDUSTRY A paper mill has several high-risk areas where a fire or an explosion can occur. Examples of high-risk areas are IR-dryers, mills and filters. FIREFLY IR-GUARD™ An IR-dryer is the most dangerous and common source of a fire in the paper industry. A fire in the IR-drying area can result in long and costly downtime. Firefly's IR-Guard™ solution is a Quick Suppression System and includes quick flame detection and water mist suppression, providing optimal protection of one of the most valued links in the production chain. Firefly protects paper mills and filters with IR-radiation detection of sparks and hot particles and extinguishing using water spray, isolation with CO2 or water mist suppression. FIREFLY YANKEE HOOD PROTECTION

FIREFLY DOCTOR BLADE PROTECTION

|