|

|

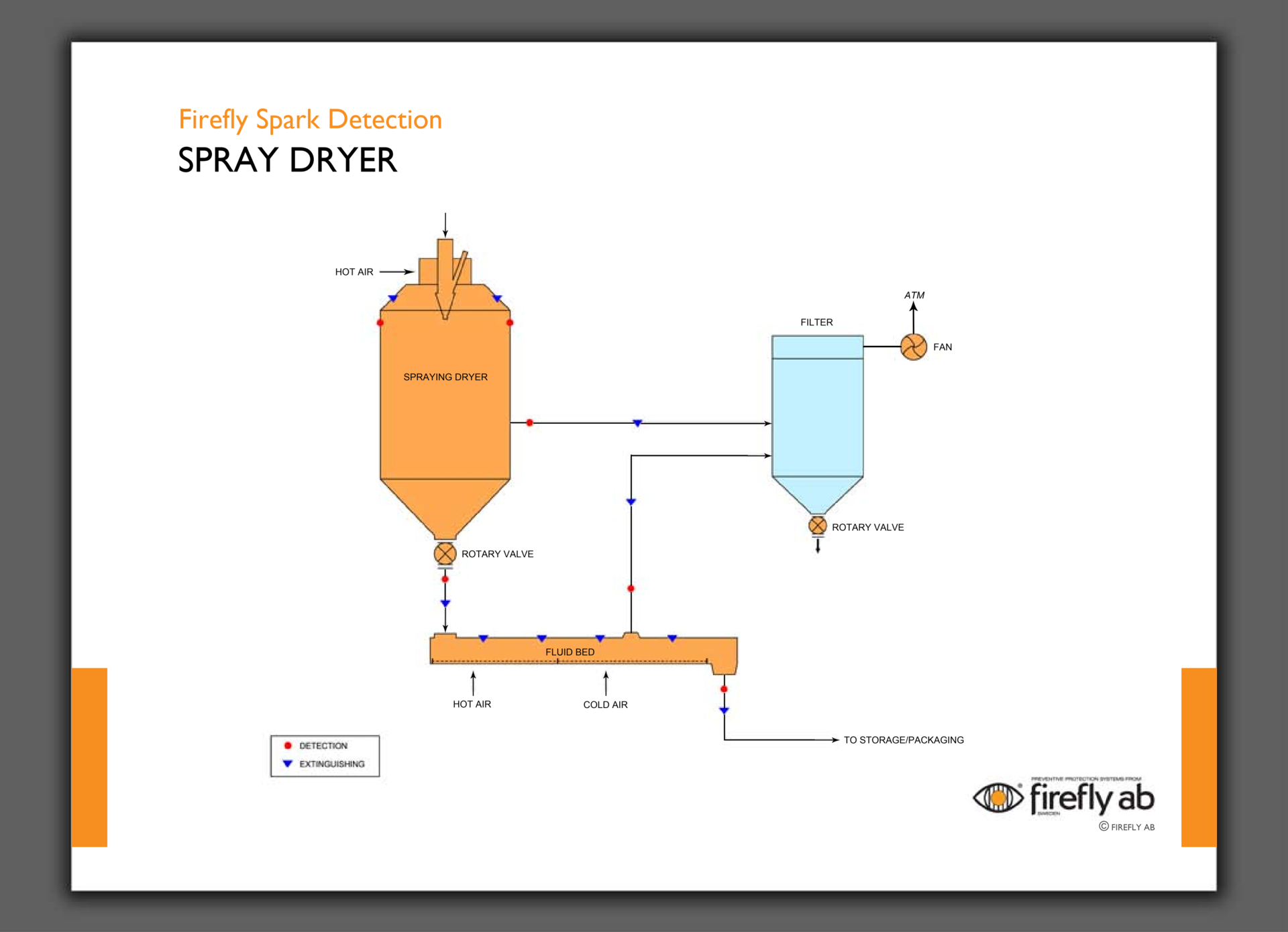

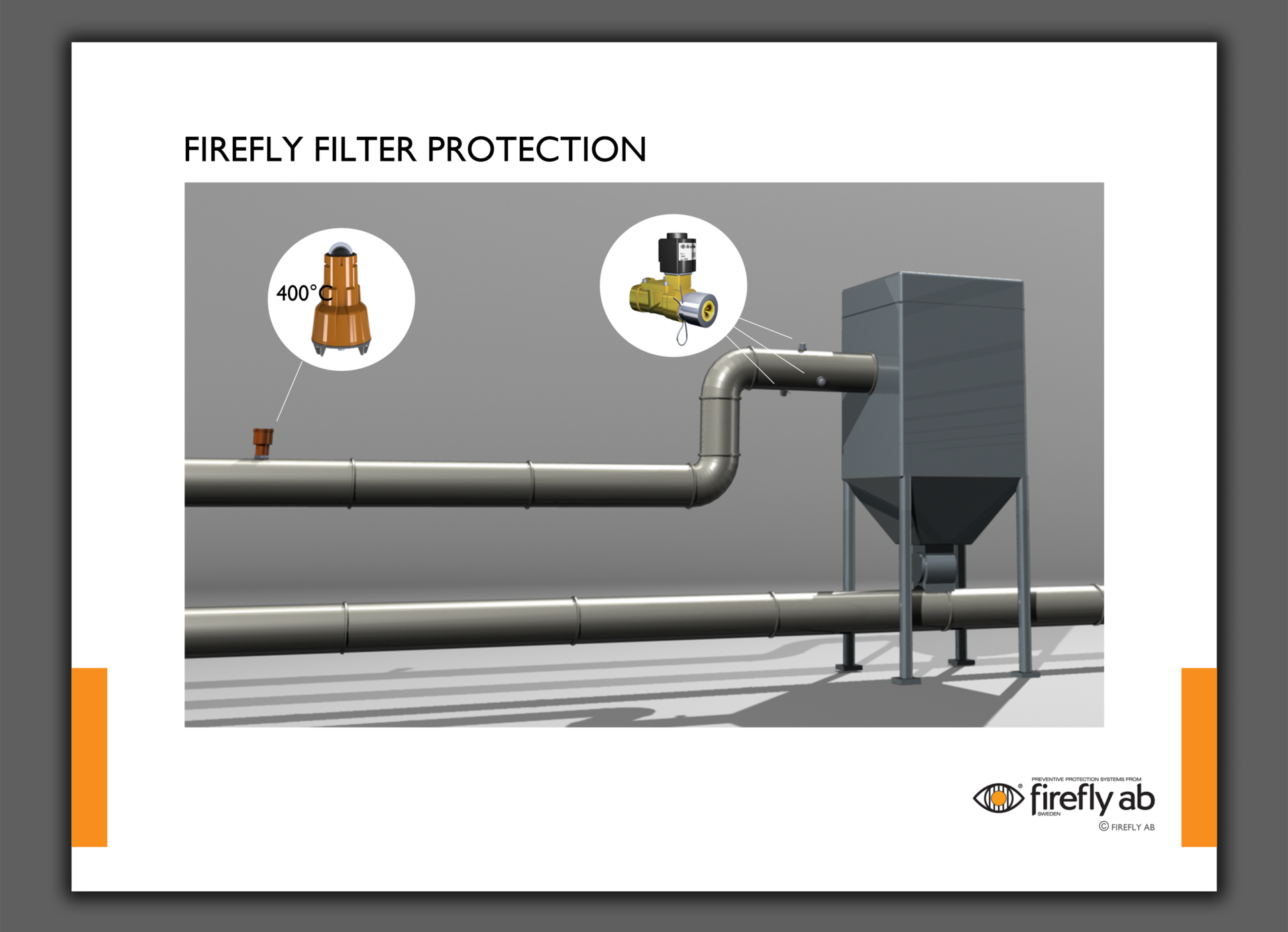

FIRE PROTECTION IN THE FOOD INDUSTRY The food industry cannot be generalized as it contains a wide range of processes. One common denominator for the food industry is that its materials are fine, dry, and in most cases organic. These materials can ignite and explode if an ignition source is present in a layer or within a dust cloud. The codes for the use of equipment in the food industry are very strict. Firefly therefore tailors a protection system to accommodate these parameters. Firefly equipment for the food industry contains of stainless steel and other food-approved materials. To provide effective protection against fires and explosions, Firefly offers fire protection through Spark Detection and Quick Suppression solutions by using IR-radiation detection and flame detection in combination with water spray extinguishing and water mist suppression. FIRE PROTECTION SOLUTIONS FOR THE CACAO INDUSTRY Risk areas in a cacao plant are the roaster, cake breaker, mill and the silo/storage area. In all these areas, overheated particles and other ignition sources can create a fire or explosion. Firefly offers tailor-made systems for the protection of cacao plants. With the aim to avoid unnecessary interruptions and damages to the process, Firefly offers fast IR radiation detection in combination with effective suppression. FIRE PROTECTION SOLUTIONS FOR THE CEREAL PRODUCTION INDUSTRY Overheated cereals that are transported in the process are one of the main causes of the fire-related problems in the cereal production industry. Firefly offers tailor-made systems for the protection of cereal production. With the aim to avoid unnecessary interruptions and damages to the process, Firefly offers fast IR radiation detection in combination with suppression and/or diversion. BAKED PRODUCTS FIRE PROTECTION SOLUTIONS FOR BAKED PRODUCTS Baked products are always exposed to high temperatures from ovens. Taking into account that almost all baked products have ignition temperatures very close to the average oven operation temperature, there is a constant latent risk that products will burn. This risk increases due to possible failures in temperature calibration of ovens and maintenance issues. High temperatures in the process can cause overheating of the baked products, which many times turn into flames or embers. This can lead into possible damages of the cooling and transport band, as well as bad product quality and possible packaging problems. FIREFLY SPARK DETECTION SPRAY DRYER

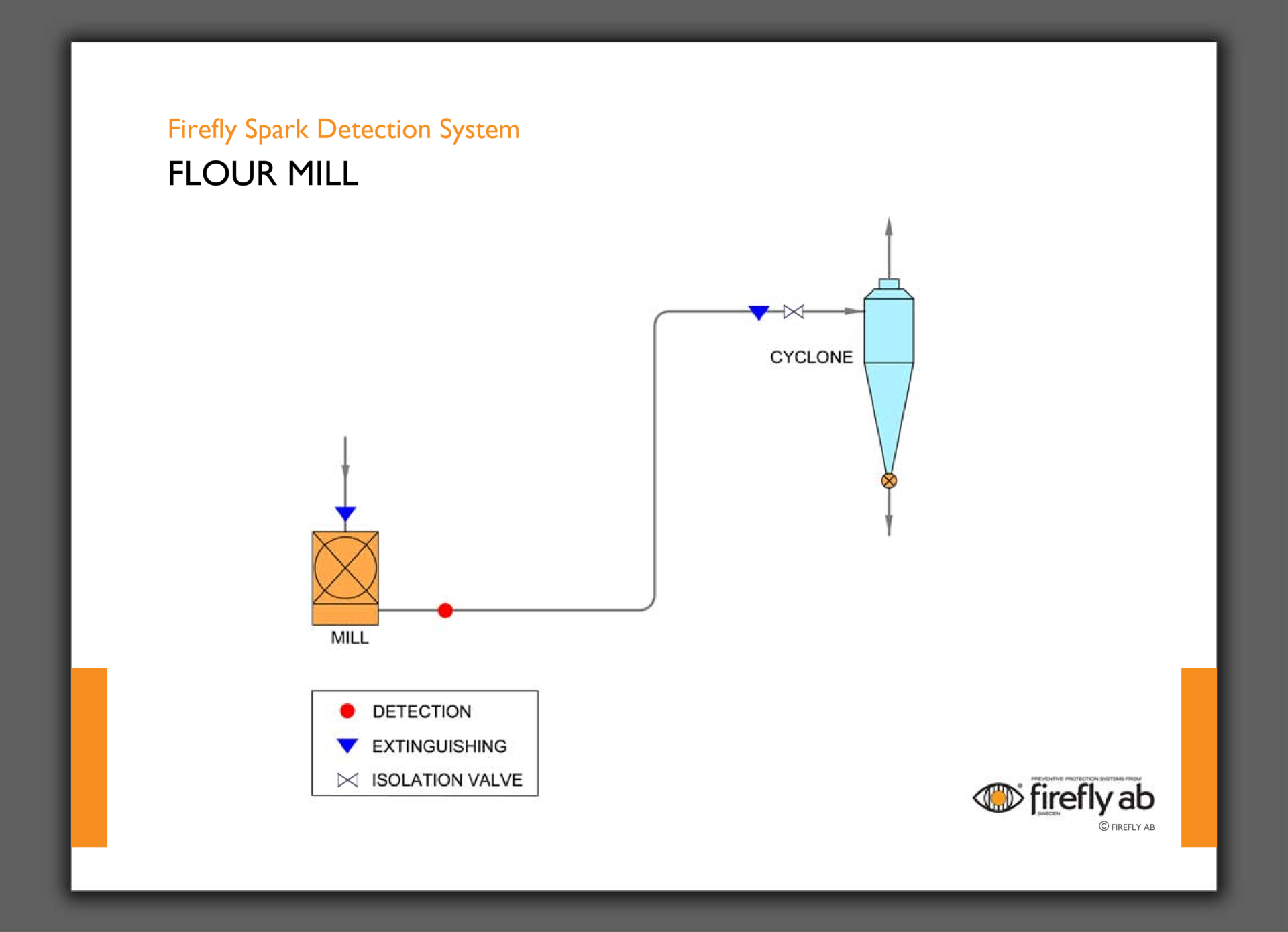

FIREFLY SPARK DETECTION SYSTEM FLOUR MILL

|